Product Description

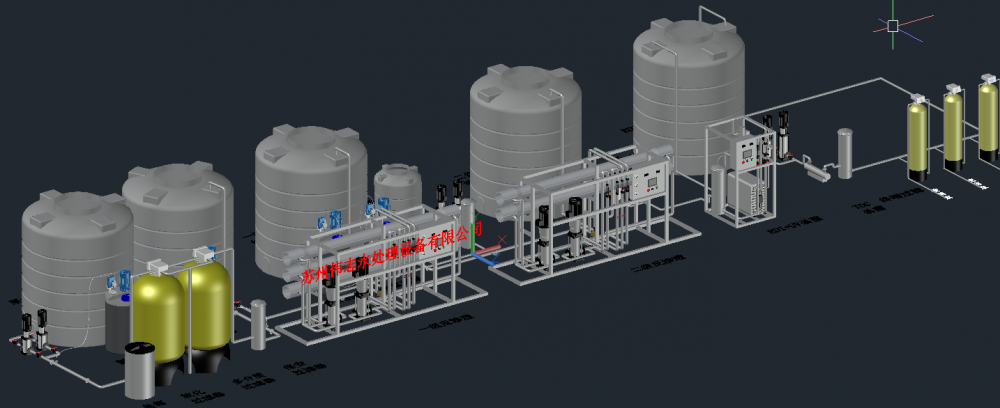

First-Level Reverse Osmosis Pure Water Equipment

Pure water equipment , it uses mainly reverse osmosis membrane technology. Industrial Pure Water Equipment working principle is to apply a certain pressure to the water to make the water molecules and ionic mineral elements pass through the reverse osmosis membrane, and most of the inorganic salts (including heavy metals), organic matter, bacteria and viruses dissolved in the water are impenetrable. Pass the reverse osmosis membrane, so that the pure water that has been permeated and the concentrated water that cannot be permeated are strictly separated; the pore size on the reverse osmosis membrane is only 0.0001 microns, while the diameter of the virus is generally 0.02-0.4 microns, and the diameter of ordinary bacteria is 0.4 -1 micron.

Process introduction:

(1) Pretreatment system:

①Quartz Sand Filter

Quartz sand filter is used to remove the suspended solids, silt, impurities, etc. of the larger particles in the raw water, and reduce the turbidity of the water. Moreover, the organic matter, bacteria, viruses, etc. in the water can be removed in large quantities as the turbidity decreases, and it creates good conditions for disinfection after filtration.

②Activated carbon filter

Use the adsorption capacity of activated carbon to effectively adsorb organic matter, free residual chlorine, colloids, particles, microorganisms, certain metal ions and decolorization in raw water.

③Softening system (dosing system)

Using the exchange performance of the ion resin to remove calcium and magnesium ions in the raw water to prevent the impact of scale formation on subsequent equipment, but the operation is labor-intensive and material-consuming. Change the dosing system to directly add the scale inhibitor to it.

(2) Reverse osmosis system

Reverse osmosis, also known as reverse osmosis, is a membrane separation operation that uses pressure difference as the driving force to separate solvent from solution. Because it is opposite to the direction of natural penetration, it is called reverse osmosis. According to the different osmotic pressure of various materials, the reverse osmosis pressure greater than the osmotic pressure can be used, that is, the reverse osmosis method, to achieve the purpose of separation, extraction, purification and concentration.

Two: Ultra-pure water equipment

Ultra-pure water equipment adopts pretreatment, reverse osmosis technology, ultra-purification treatment and post-treatment methods to almost completely remove the conductive medium in the water, and remove the non-dissociated colloidal substances, gases and organic substances in the water to a very low level. Water treatment equipment.

Ultra-pure water equipment was originally produced by the U.S. science and technology community in order to develop ultra-pure materials (semiconductor original materials, nano-fine ceramic materials, etc.) using distillation, deionization, reverse osmosis technology or Other appropriate supercritical fine technology. Except for water molecules (H20), there are almost no impurities in the water, and there are no bacteria, viruses, chlorinated dioxins and other organic substances. Of course, there are no minerals and trace elements required by the human body. Ultra-pure water is difficult to achieve by ordinary processes. For example, if the resistivity of water is greater than 18MΩ*cm and close to 18.25MΩ*cm, it is called ultrapure water.

Cosmetic Pure Water Equipment Process introduction:

(1) Pretreatment system:

①Quartz sand filter

Quartz sand filter is used to remove the suspended solids, silt, impurities, etc. of the larger particles in the raw water, and reduce the turbidity of the water. It can also make the organic substances, bacteria, viruses, etc. in the water be removed in large quantities as the turbidity decreases, and create good conditions for disinfection after filtration.

②Activated carbon filter

Use the adsorption capacity of activated carbon to effectively adsorb organic matter, free residual chlorine, colloids, particles, microorganisms, certain metal ions and decolorization in raw water.

③Softening system (dosing system)

Using the exchange performance of the ion resin to remove calcium and magnesium ions in the raw water to prevent the impact of scale formation on subsequent equipment, but the operation is labor-intensive and material-consuming. Change the dosing system to directly add the scale inhibitor to it.

(2) Secondary reverse osmosis system

Reverse osmosis, also known as reverse osmosis, is a membrane separation operation that uses pressure difference as the driving force to separate solvent from solution. Because it is opposite to the direction of natural penetration, it is called reverse osmosis. According to the different osmotic pressure of various materials, the reverse osmosis pressure greater than the osmotic pressure can be used, that is, the reverse osmosis method, to achieve the purpose of separation, extraction, purification and concentration.

(3) EDI system

The EDI membrane stack is composed of a certain number of units sandwiched between two electrodes. There are two different types of chambers in each unit: the fresh water chamber to be desalinated and the concentrated water chamber to collect the removed impurity ions. The fresh water chamber is filled with mixed cation and anion exchange resins. These resins are located between two membranes: a cation exchange membrane that only allows cations to pass through and an anion exchange membrane that only allows anions to pass through. The resin bed is continuously regenerated by the direct current applied to both ends of the chamber. The voltage decomposes the water molecules in the incoming water into H+ and OH-. These ions in the water are attracted by the corresponding electrodes and pass through the cation and anion exchange resin to the corresponding membrane. When these ions enter the concentration chamber through the exchange membrane, H + and OH- combine to form water. This generation and migration of H+ and OH- is the mechanism by which the resin can achieve continuous regeneration.

EDI can replace the traditional mixed ion exchange technology (MB-DI) to produce stable deionized water. Compared with mixed ion exchange technology, EDI technology has the following advantages:

①The amount of ion exchange resin is small, about 5% of the amount of resin in the traditional ion exchange method.

②Ion exchange resin does not need acid and alkali chemical regeneration, saving a lot of acid, alkali and cleaning water, greatly reducing labor intensity.

③ No waste acid and waste lye are discharged. It is a clean production technology and an environmentally friendly product.

④The process is easy to realize automatic control, and the quality of produced water is stable. Combined with RO and other water treatment technologies, it can form a complete pure water and ultra-pure water production line.

⑤The produced water quality is high, which can reach the national electronic grade water level I standard, the resistivity is 15-18MΩ·cm, and the bacterial endotoxin content is less than 0.1mg/L, which can fully meet the requirements of the Chinese Pharmacopoeia and the United States Pharmacopoeia for medicinal water Require.

⑥ It has excellent ability to remove weakly dissociated substances (such as carbon dioxide, silicon, boron, ammonia, etc.), which is more suitable for the needs of ultra-pure water.

⑦The pure water production process is continuous, and there is no need to repeat the setting in a set of regenerating sets like an ion exchange bed.

(4) Polishing finishing system

Polishing mixed bed, also known as disposable mixed bed, is generally used at the end of the process to further improve the quality of water produced. The resin in the polishing mixed bed cannot be regenerated and reused. The so-called polishing means the surface treatment of the resin.

In order to obtain theoretical pure water with a conductivity of 0.055μS/cm (resistivity 18.2 MΩ·cm) used in electronics, medicine or other industries, after ordinary mixed bed or EDI water purification equipment, a polishing mixed bed is usually installed for final refinement. deal with. The resin for polishing mixed bed is a mixture of anion resin and cation resin with close relative density. Since the anion and cation resin of this resin cannot be separated, they cannot be regenerated separately with acid and alkali, so after the polishing resin fails , Discarded.

Product Categories : Pure Water Equipment > First-level Reverse Osmosis Pure Water Equipment